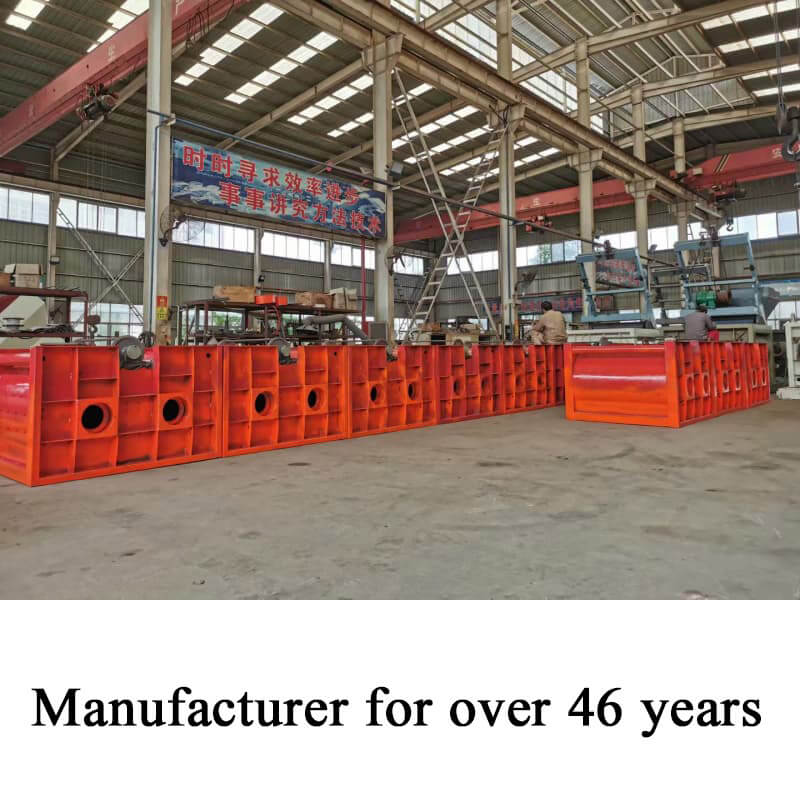

Introduction

Our vertical planetary mixers have high quality, high efficiency, uniform mixing without dead angles and are used in building materials, concrete (dry hard, semi-dry hard, plastic concrete, ultra-high performance concrete, fiber concrete), refractory materials, chemicals, casting, metallurgy, ceramics, glass and other industries to solve the problem of mixing process requiring high homogeneity of materials.

Our vertical planetary mixers have high quality, high efficiency, uniform mixing without dead angles and are used in building materials, concrete (dry hard, semi-dry hard, plastic concrete, ultra-high performance concrete, fiber concrete), refractory materials, chemicals, casting, metallurgy, ceramics, glass and other industries to solve the problem of mixing process requiring high homogeneity of materials.Main Details

Mixing System

1. Continuous stirring track and high mixing efficiency.

2. Reduce the wear of lining plates and blades.

3. The bottom scraper and the side scraper have automatic cleaning function.

Discharging System

1. Pneumatic or hydraulic can be selected.

2. The discharge door is equipped with a special sealing strip, which is reliable in sealing.

3. Manual unloading device, which can manually unload the materials in the mixing barrel in case of emergency.

Observation Port

Convenient maintenance, you can observe the situation of mixing materials when the mixer works normally under the state of uninterrupted power supply.

Transmission

1. Adopt large module gear, with high transmission reliability, strong stability and long service life.

2. Simple structure, more reasonable stress, less noise and more convenient maintenance.

Injector

The nozzle adopts spiral solid conical nozzle,which has fine and uniform atomization effect,large coverage area and uniform mixing of materials.

360 Mixing Without Dead Angle

1.The trajectory of the mixing arm is more complex and dense,and there is no dead angle in 360 mixing,so the mixing of materials is more sufficient.

2.Strong power,low noise,reducing energy consumption on the premise of mixing.

Advantages

Service

Pre-sale Services

- Quick response.

- Provide detailed quotation.

- Provide scheme design and site planning.

- Accept customer's visit.

On-sale Services

1. If necessary, send technicians to the site for installation and commissioning.

2. Provide complete technical information.

3. Free training of operators.

After-sale Services

- One year warranty for mixing equipment, two years warranty for core electrical appliances, free accessories for quality problems during the warranty period, except for wearing parts.

- Make regular remote visits.

- Lifelong after-sales technical support service.

Delivery

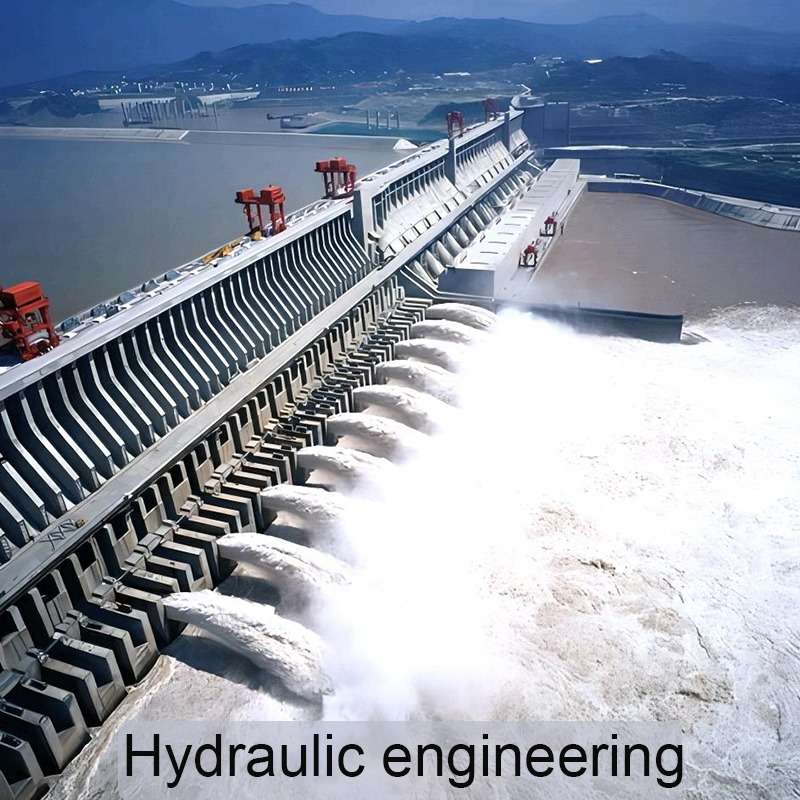

Application