Introduction

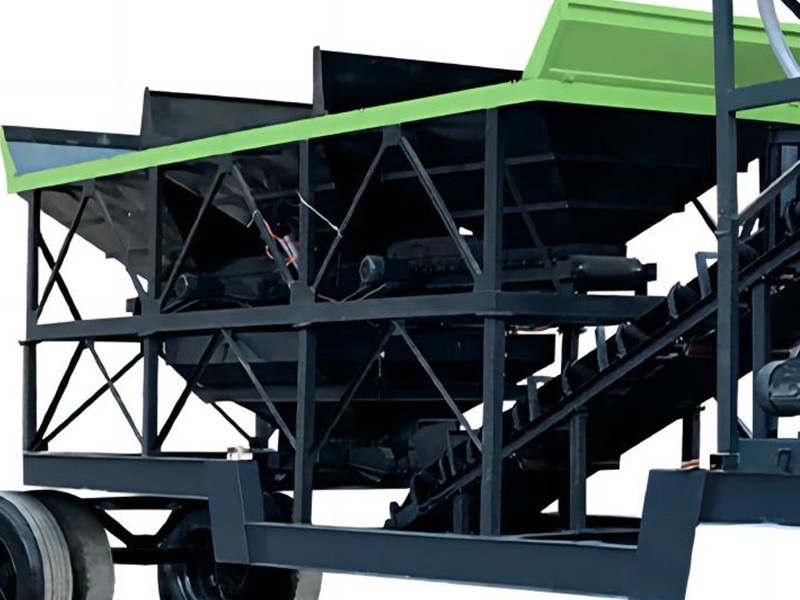

YHZM25 mobile drum concrete mixing plant adopts a JZM500 drum concrete mixer, batching machine adopts a PLD800 batching machine, the theoretical output is 25 cubic meters per hour.

YHZM25 mobile drum concrete mixing plant adopts a JZM500 drum concrete mixer, batching machine adopts a PLD800 batching machine, the theoretical output is 25 cubic meters per hour.Main Details

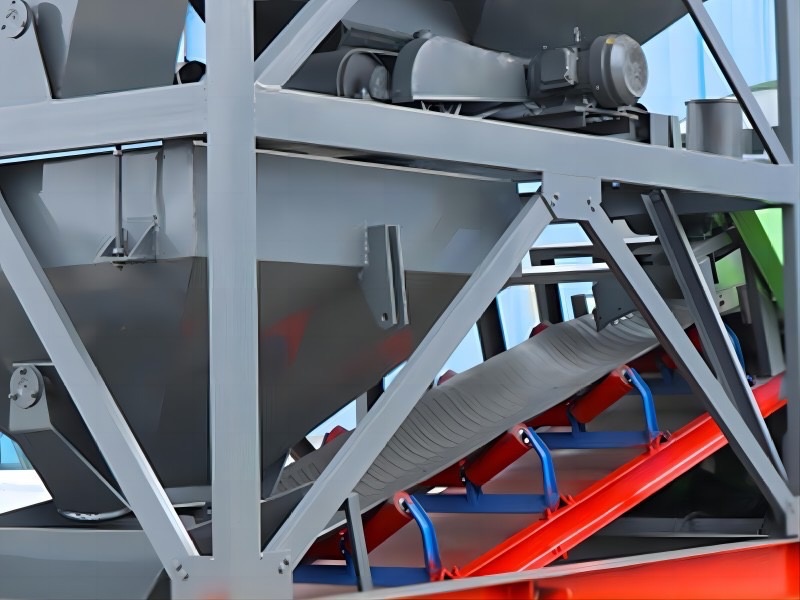

Mixing System

- Adopt rubber roller to drive the drum, with low noise, stable performance, simple operation and convenient movement, and more uniform stirring.

- Can mix a variety of concrete such as fluidity, semi-hardness and hardness.

Weighing System

- Powder and water or additives are measured independently, ensuring fast and high accuracy weighing.

- Famous brand sensor ensures the error no more than 1%.

Aggregate Batching System

- Sand storage bin is with large vibrator, guarantee smooth and fast discharge.

- Accumulative weighing system or separate weighing system is available choice.

- High accuracy sensor ensures the error no more than 2%.

Aggregate Conveying System

- Inclined angle up to 32 degree, stand small area.

- Equipped with recycled belt conveyor to reuse the leakage material.

- Vibrating Return cover to avoid sticks.

Control System

- Automatic or manual can be adjusted flexibly smoothly.

- All wires & cables are coded, easy to track and maintenance.

- Intelligent management system for task tracking, printing, etc.

- Computer+ PLC control system to ensure simple and stable operation, HD display can show clearly about the operation of each part.

Cement Screw Conveyor

- High revolving speed, large conveying capacity and high precision.

- Easy assemble, easy connection and reliable sealing.

- Suitable for conveying a variety of powder, granular, small bulk materials.

- Diameter as φ219mm/φ273mm/φ325mm, lengths as 6m, 8m or 10m, all can be customized.

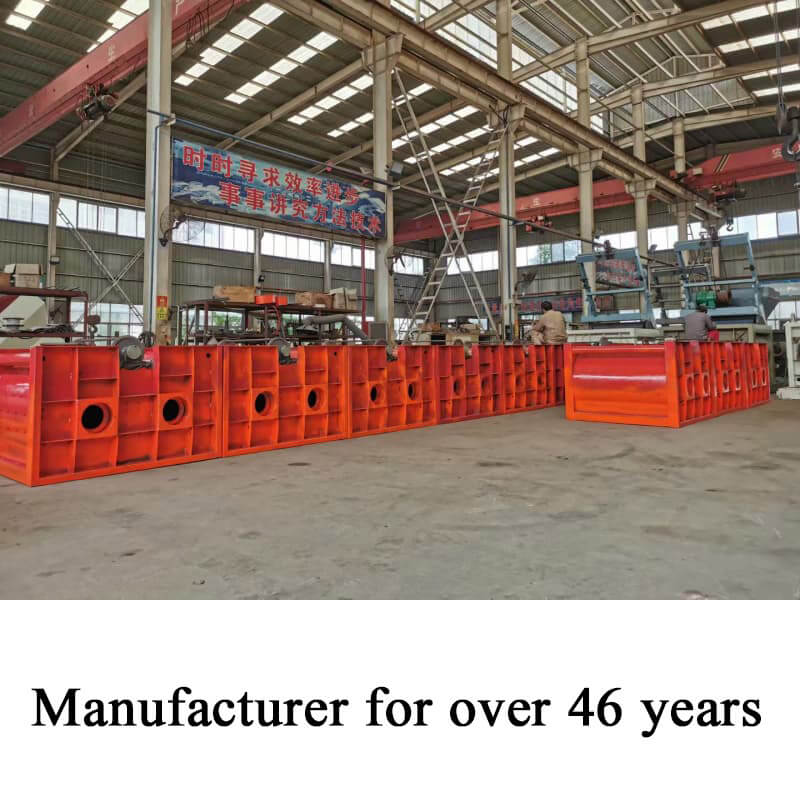

Cement Silo

- Vertical or horizontal cement silo is available for selection.

- Capacity range from 50T to 300T can be customized.

- Accessories are including air-break device, gate valve, relief valve, level meter, dust collector, etc.

- High-quality steel, good sealing, stable support and long service life.

Advantages

Service

Pre-sale Services

- Quick response.

- Provide detailed quotation.

- Provide scheme design and site planning.

- Accept customer's visit.

On-sale Services

1. If necessary, send technicians to the site for installation and commissioning.

2. Provide complete technical information.

3. Free training of operators.

After-sale Services

- One year warranty for mixing equipment, two years warranty for core electrical appliances, free accessories for quality problems during the warranty period, except for wearing parts.

- Make regular remote visits.

- Lifelong after-sales technical support service.

Delivery

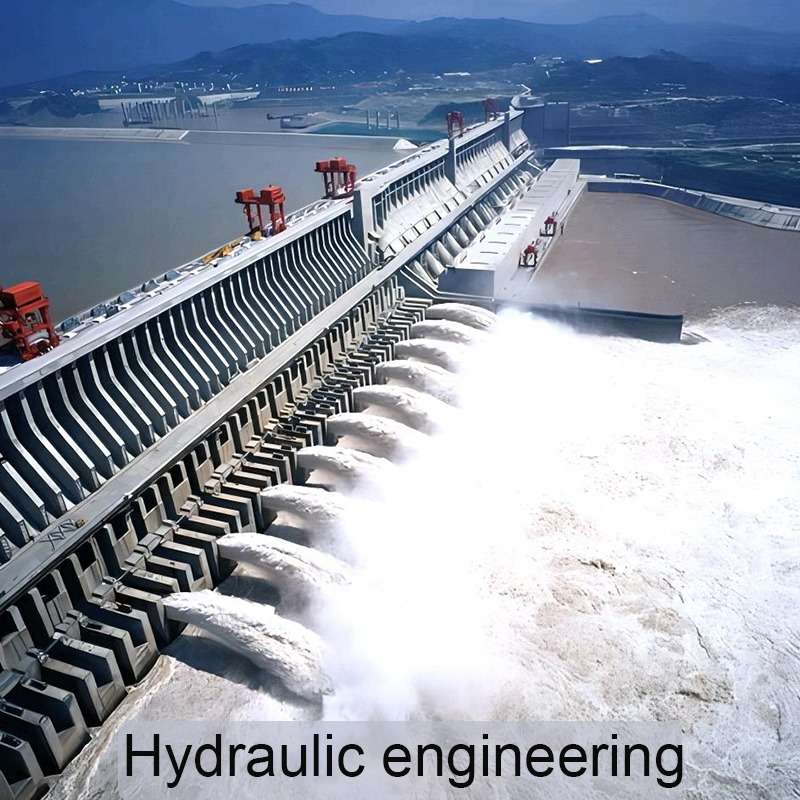

Application